Food Machinery

At Food Machinery, Imports and Servicing we are proud to represent and be supported by ReePack, We are excited to be able to bring this range of Machines to New Zealand.

At Food Machinery, Imports and Servicing we are committed to provide our customers with high quality processing solutions with the highest hygienic and safety standards, in cooperation with our customers. This applies not only to machinery but also to outstanding maintenance and support.

REEPACK

ReePack Vacuum Packaging Machinery are designed for the medium to large operations. These machines are custom built for your operation and are user friendly. They have the functionality of their 'cousins' in the market but not the price tag.

AUTOMATIC TRAY SEALERS

REEPACK is one of leading manufacturer of FULLY AUTOMATIC tray-sealers machine. Our target is to meet Customer requirements with regard to tray quality and product to load. We propose these 3 models of stand-alone fully automatic heat-sealing machines that offering throughputs from 4 up to 24 packs per minute. Machines in range are capable of a solid sealing, Modified atmosphere process (M.A.P.) and Vacuum Skin Packages (V.S.P.). The packages are made sealing top film and pre-formed tray together in a special die. Different kinds of material are suitable for different purposes as PP, PE, PS, C-PET, A-PET, EPP, EPET, Cardboard, Alu etc. All these REEPACK automatic traysealer machines operate only with electric source (Eco-line) excluding any pneumatic support. Electrically operated is an ideal system where mobility, servicing and energy saving is a top priority.

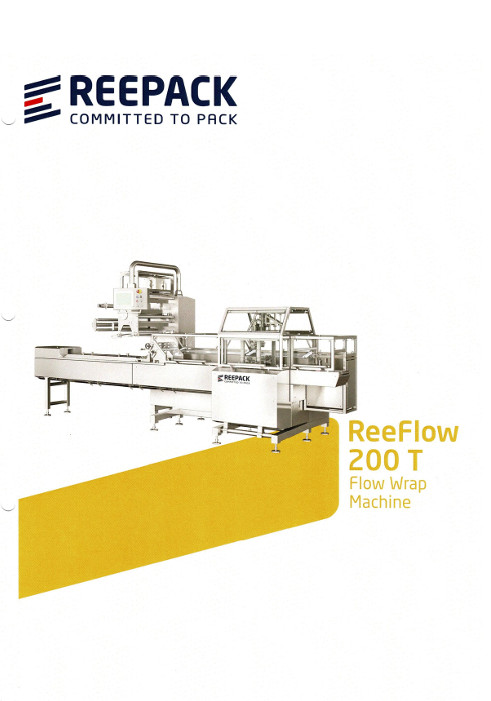

FLOW WRAP

Horizontal Flow Wrapper (HFFS) that makes a totally hermetic three sealing pillow pack for fresh food in modified atmosphere (MAP). High performance level. Reeflow 200 LO is a machine developed to pack fresh food products in a Flow-Pack (pillow pack) style bag with three seals, and it incorporates the state of the art of packaging technology, to satisfy the most exigent requirements in the food industry. The construction in stainless steel and on a cantilevered frame, its high degree of protection against moisture, together with its design made of parts that can be easily disassembled to sanitize the machine, turn the Reeflow 200 LO machine into the ideal packaging machine for a very wide range of applications in the fresh food industry.

SEMI-AUTOMATIC TRAY SEALER

The main technology of Reepack is the preservation and protection of any kind of food, fresh or cooked, in preformed trays. Our extensive range of semi-automatic heat-sealing machines offer output of up to 24 packs per minute. The machines in our range are capable of either sealing only or closure with modified atmosphere (Vacuum&Gas). The packages are produced by sealing top film and tray together in the sealing die. Different kind of materials can be used for different purposes as PP, PE, PS, C-PET, A-PET, EPP, EPET, Cardboard, Alu etc.

THERMOFORMING

Reepack thermoforming packaging machines offer a wide range of machines to meet any individual requirements. From entry-level to flexible and compact models up to high performance machines processing flexible and rigid film, with different thickness for several film width, forming depth and cut-off lenght. The machines frame and sheeting are all in stainless steel for easy sanitation in wash down environments. An easy open frame allows access to check adjust and repair all parts of the machine. All of the system is located inside the machine frame and protected from any damage. An user-friendly HMI controller provides the operators with an easy setting and recording of different programs. Freely programmable movements result in maximum flexibility with respect to different formats and products. Several options with different features can be added to the machines to fullfill any packaging demand. Our thermoformers operate mostly with electric source (Eco-line) excluding any pneumatic support. Electrically operated is an ideal system where performance, servicing and energy saving is a top priority.

VACUUM CHAMBER

Automatic vacuum packaging machines designed to meet the best preservation in shrinkable, multilayer and aluminium flexible paunches. It is possible to pack under vacuum: sausages, ham, bacon, poultry, fish, cheese, pasta and other speciality Foods. Frame, working table and chamber, with their accessories are fully stainless steel manufactured. Overall control by micro PLC with 10 storable programs. • Digital control of the vacuum and the sealing temperature. • Bi-active sealing. The broad band sealing device mounted on the sealing bar and counterbar, secures a perfect sealing which can even withstand an autoclave sterilisation. • Both models are provided with two sealing groups, placed on the long sides, independently usable. • A pre-sealing phase is to remove flats or fluids from the sealing area. When using special thick or heavy duty pouches, it is possible to have additional pressure on the sealing bar with the aid of compressed air. • Pneumatic movement of the chamber with a safety hydraulic brake. • Pneumatic moving guides at the infeed. • lnfeed conveyor belt with electronically adjustable speed. • Free air consumption 30 NI per cycle; working pressure 6 BAR. • The suggested external vacuum pumps grant a max. vacuum of 99,9%; possibility to achieve approx. an output of 3 cycles per two minutes according to the working options and pumps dimensions. • An higher output may be reached with the use of an additional ROOTS.