SCANSTEEL - SuperGrind 400/260

Globally, the scansteel foodtech® SuperGrind 400/260 & 550/260 are probably the toughest and most Heavy Duty “Work Horses” among meat raw material grinders. Designed specifically for global pet food and rendering industries for grinding of: • Entire beef bones - all types including femur bones. • Entire pork bones - all types including femur bones. • Poultry bones – all types. • Fish bones – all types. • Pre-broken bones. • Soft meat raw material Video shows SuperGrind 400/260 grinding entire beef hides (Fresh) through a 4mm Holeplate, with a grinding capacity of 3000-6000 kg/hour. The SuperGrind 400/260 in action grinding Horse bones with ease.

SCANSTEEL - Twin Shaft Feed Pump

(ContiPump)

The scansteel foodtech® ContiPump series is for less Heavy Duty applications such as, but not limited to, pet food premixes being fed into an emulsifier as well as for various buffer/storage/silo applications. The buffer hopper comes in 2 (two) versions: one single feeding screw or twin (two) feeding screws, where one screw feeds/drives the ContiPump while the other prevents/limits bridge building. The scansteel foodtech® ContiPump series has been designed in such a way that the unit can function as a stand alone pump or can be designed to fully be integrated as part of an integrated solution with the scansteel foodtech® ContiPump and the scansteel foodtech® mixer series. In order to secure full hygiene solutions as well as having full access to both the mixer(s) and ContiPump for inspection/maintenance. The scansteel foodtech® ContiPumps can be placed on a “rail system” which makes it fully possible for a person to separate the ContiPump and mixer. At the same time, during production, the ContiPump is secure in “running position” in such a way that the ContiPump cannot be moved.

SCANSTEEL - SuperPump

series comprises 3

The scansteel foodtech® SuperPump series comprises 3 (three) different pump sizes. Correct choice of pump depends on several factors such as, but not limited to, pump capacity, material to be pumped, temperature, viscosity, and particle size – from pre-ground meat raw material to half a pork carcass. One significant feature is the double discharge outlet which dramatically minimizes (eliminates) fluctuations in pump capacity. Pump motors are designed according to pump application.

SCANSTEEL - Whole Pallet Crusher

The scansteel foodtech® Whole Pallet Crusher, WPC, range is probably among the most comprehensive ranges available. scansteel foodtech A/S manufactures a range of Whole Pallet Crushers with either single claw or double claws with a standard infeed width of 1500mm or 2000 mm. A Whole Pallet Crusher is capable of crushing a pallet full of frozen together blocks which as such appear as one entire frozen block of, example only, 1200 x 800 x 1500 mm.

SCANSTEEL - Twin Shaft Mixer-Grinder 1250

The ScanSteel range of Mixer-Grinders are designed to meet individual requirements. The 1250Ltr Mixer-Grinder shown here has been plated, equipped with CCR (Continuous Chip Removal also known as Bone Elimination System), cooling system in the grinding lining, mirro polished container, Twin Shaft Intermeshing. Has a final grinding rate of 3000-10,000 kg/hour depending on meat raw material types and holeplates. Mixer-Grinders sizes vary from 200ltr – 3,250lt.

SCANSTEEL - Cut The Top

Cut The Top is a system that delivers one frozen block at a time to an infeed conveyor, from a stacked pallet. Less lifting for staff, less staff required.

Scan Giraff

Scansteel Foodtech A/S manufactures a wide range of screw conveyors, such as: Screw conveyors, Giraff screw conveyors and vertical screw conveyors. The Scan Giraff has been designed with a particular focus on hygienically cleaning, accessibility, assembly and disassembly of all components. scansteel foodtech® Screw conveyors are inclined and horizontal. scansteel foodtech® Giraff screw conveyors are horizontal/vertical (as one unit) scansteel foodtech® Vertical screw conveyors are for mounting directly on grinder outlets.

Scansteel Foodtech Combigrind Series

CG 225 / CG 300 / CG 300 HEAVY DUTY / CG 400 – THE BEAST

These truly unique and universal grinders provide first-class grinding results, fully comparable with and even surpassing those of conventionally specialised grinders for fresh, tempered, or deep-frozen blocks without changing anything but the incoming raw material to be ground, coarsely or finely, as required. scansteel foodtech® CombiGrind Grinders from Ø160 mm – Ø400 mm – 11 kW – 22 kW on breaking worm/auger and 30 kW – 200 kW on grinding worm/auger High performance grinding within a wide capacity range is achieved through a low-tolerance, rigid design with smoothly shaped worms, hand-forged, welded, and ground superfinely by skilled Danish craftsmen combined with the smooth surfaces of a high precision CNC milling lining. Equipped with a feeding and grinding worm/auger. Equipped with scanControl system, which monitors the frequency convertors on the two worms, regulating grinding speed in case of overloading. Level sensor programme for automatic Start/Stop of machine to ensure machines are not running empty. The CombiGrind machines have been designed to enable easy assembly and disassembly.

SCANSTEEL - Worm Trolley

This trolley designed by ScanSteel FoodTech allows operators to safely remove and insert the worm/auger for cleaning and inspection – without heavy lifting.

SCANSTEEL - GRINDER – SINGLE WORM

MG 330

The scansteel foodtech® MG 330 is equipped with either 75 kW or 90 kW electrical motor depending on specific grinding application(s). The MG 330 grinder is incredibly strong and reliable for both frozen blocks of meat raw material of any type as well as for certain bone-in products plus fresh meat raw materials. It comes with either a fixed or a loose pre-cutter depending on the grinding application. Shown here grinding frozen Pig Skin.

SCANSTEEL - DOUBLE WORM COMBIGRIND

CG 300 / CG 300 HEAVY DUTY

These truly unique and universal grinders provide first-class grinding results, fully comparable with and even surpassing those of conventionally specialised grinders for fresh, tempered, or deep-frozen blocks without changing anything but the incoming raw material to be ground, coarsely or finely, as required. scansteel foodtech® CombiGrind Grinders from Ø160 mm – Ø400 mm – 11 kW – 22 kW on breaking worm/auger and 30 kW – 200 kW on grinding worm/auger High performance grinding within a wide capacity range is achieved through a low-tolerance, rigid design with smoothly shaped worms, hand-forged, welded, and ground superfinely by skilled Danish craftsmen combined with the smooth surfaces of a high precision CNC milling lining. Shown here grinding whole frozen goat.

SCANSTEEL - Emulsifier

MG250

The industry “Work Horse” – scansteel foodtech® emulsifier does it all! The scansteel foodtech® MC 250 & MC 300 emulsifiers have a unique dual feeding/two steps feeding system: • Stand-alone feeding pump, feeding the lining/housing of the MC 250 & MC 300. • Feeding/crushing screw, feeding the knife set. The feeding pump with its own feeding screw with block breaking/bone breaking capabilities force-feeds the scansteel foodtech® MC 250 & MC 300 emulsifier lining/housing. Entering the lining/housing, the feeding screw of the MC 250 & MC 300 further force-feeds/grinds any particles, being frozen meat raw materials and/or bones. The feeding screw with its recessed 3-bladed knife distributes any products continuously towards the first hole plate securing optimal cutting/emulsifying effect.

SCANDEFROST SDV FROM 2000 L - 12,000 L

WITH VACUUM & BOTTOM DIRECT STEAM INJECTION VACUUM DEFROSTING

With scansteel foodtech® scanDefrost technology Defrost pre-ground/crushed frozen meat and poultry blocks in minutes, (not hours!) Frozen blocks directly from the freezer down to 30°C, even before pre grinding/crushing. Advantages – No driploss, no tempering or thawing required, gentle to meat and does not cause denaturation or discolouration, binding materials of meat remain.

SCANSTEEL - Cheese and Butter Folder

CHEESE & BUTTER EXTRUDER SERIES MGX 250/300/400

Scansteel foodtech A/S manufactures and supplies a range of cheese extruders, model MGX 250/300/400, respectively. Extruders can be supplied as stand-alone equipment or as part of an entire cheese processing line. High output to meet high production rate demands up to 12,000 kg/hr. Lower formulation costs as high surface area/small particle size of Ø2.8/ Ø5 or Ø14mm lead to increased utilisation of functional components, i.e. young cheese intact casein due to increased and consistent melting and protein hydration/emulsification capabilities. Minimum risk of foreign matter: no metal-to-metal contact surfaces because of foreign matter separation. Performance capability: high output up to 12,000 kg/hr and particle size Ø2.8, Ø,5 or Ø14 mm. Capable to extrude frozen cheese and butter.

Thurne

High Performance Slicing Systems, Thurne has been supplying innovative slicing systems to the bacon, fresh and cooked meats and cheese industry for more than 50 years. Your Thurne Advantage ENHANCING PERFORMANCE Thurne has been pushing the boundaries of slicing technology since 1967, continuously innovating systems that maximise yield and throughput. WE KNOW BACON! With more than 50 years experience in retail and foodservice bacon applications, Thurne is THE trusted advisor in the bacon processing industry.

REVIC

REVIC was founded in 2002 and since then became one of the leaders in its segment. Our aim is to be one the most recognized brand of meat processing machines. Main advantages of REVIC are high quality, durability, reliability and great service. Wide range of products and pioneer solutions proves that REVIC consists of highly-skilled and experienced specialists. Our mixing, grinding, slaughtering and hygienic equipment is available in either standard or custom designs, to meet your specific needs. The company has a growing reputation for innovative engineering, durable construction and great price

ReePack

ReePack Vacuum Packaging Machinery are designed for the medium to large operations. These machines are custom built for your operation and are user friendly. They have the functionality of their 'cousins' in the market but not the price tag.

FMT

Canning and Sterilisation Machinery offered by this Italian company FMT

CG300

CG300 is a fairly heavy-duty machine, capable of grinding -18°C with a 5mm Holeplate. Works with two worms a pre-breaking worm and a grinding worm.

Video shows CG300 grinding various types of product.

Frozen blocks Whole frozen chicken frames though a 30m holeplate and to a deboner.

Plate frozen slabs of Hoki.

Whole frozen Tuna through a 5-7mm stepped holeplate.

MG330

MG330 is a heavy duty grinder, capable of grinding most products. Uses a single worm and has High Capacity. Video shows MG330 grinding various frozen blocks.

MG400

Video shows MG400 grinding various frozen blocks. MG400 is a heavy duty grinder, capable of grinding most products. Uses a single worm and has High Capacity. Video shows MG400 grinding Plate frozen blocks.

Supergrind 400

The ‘Beast’ is a Super Heavy Duty grinder with a single worm. Video shows the Supergrind 400 grinding beef bones through a 30mm holeplate and then on to a deboner.

Whole Pallet Double Crusher

Powerful twin shaft pre-breaker, designed to break down frozen product prior to mincing. Video shows Whole Pallet Double Crusher breaking down Plate frozen blocks of pre-ground material. This is a twin shaft crusher.

Vacuum sealers and sous-vide cookers

Vacuum sealers and sous-vide cookers from KOMET are suitable for a wide range of industries, purposes and target groups: from industrial use to butchers, caterers and the food trade to gastronomy, the hotel industry and the ambitious amateur cook - but also for anglers, bartenders or market stall operators .

ScanSteel CG300 MG330 MG400 Supergrind 400 Pallet Crusher Machinery videos

ScanSteel Videos

Cheese and Butter Folder

CHEESE & BUTTER EXTRUDER SERIES MGX 250/300/400

Scansteel foodtech A/S manufactures and supplies a range of cheese extruders, model MGX 250/300/400, respectively. Extruders can be supplied as stand-alone equipment or as part of an entire cheese processing line. High output to meet high production rate demands up to 12,000 kg/hr. Lower formulation costs as high surface area/small particle size of Ø2.8/ Ø5 or Ø14mm lead to increased utilisation of functional components, i.e. young cheese intact casein due to increased and consistent melting and protein hydration/emulsification capabilities. Minimum risk of foreign matter: no metal-to-metal contact surfaces because of foreign matter separation. Performance capability: high output up to 12,000 kg/hr and particle size Ø2.8, Ø,5 or Ø14 mm. Capable to extrude frozen cheese and butter.

Use this description for both the Cheese Extruder vids

Cheese Mixer TSMV 2750

A twin shaft mixer designed for short but through mixing times. Mixing Wings are controlled by frequency convertors to control speed and direction.

Defrost Machinery videos

SCANDEFROST SDV FROM 2000 L – 12,000 L – WITH VACUUM & BOTTOM DIRECT STEAM INJECTION VACUUM DEFROSTING – with scansteel foodtech® scanDefrost technology

Defrost pre-ground/crushed frozen meat and poultry blocks in minutes, (not hours!) Frozen blocks directly from the freezer down to 30°C, even before pre grinding/crushing.

Advantages – No driploss, no tempering or thawing required, gentle to meat and does not cause denaturation or discolouration, binding materials of meat remain.

Emulsifier Machinery videos

MC 250

The industry “Work Horse” – scansteel foodtech® emulsifier does it all! The scansteel foodtech® MC 250 & MC 300 emulsifiers have a unique dual feeding/two steps feeding system: • Stand-alone feeding pump, feeding the lining/housing of the MC 250 & MC 300. • Feeding/crushing screw, feeding the knife set. The feeding pump with its own feeding screw with block breaking/bone breaking capabilities force-feeds the scansteel foodtech® MC 250 & MC 300 emulsifier lining/housing. Entering the lining/housing, the feeding screw of the MC 250 & MC 300 further force-feeds/grinds any particles, being frozen meat raw materials and/or bones. The feeding screw with its recessed 3-bladed knife distributes any products continuously towards the first hole plate securing optimal cutting/emulsifying effect.

Grinders Folder

DOUBLE WORM COMBIGRIND CG 300 / CG 300 HEAVY DUTY

These truly unique and universal grinders provide first-class grinding results, fully comparable with and even surpassing those of conventionally specialised grinders for fresh, tempered, or deep-frozen blocks without changing anything but the incoming raw material to be ground, coarsely or finely, as required. scansteel foodtech® CombiGrind Grinders from Ø160 mm – Ø400 mm – 11 kW – 22 kW on breaking worm/auger and 30 kW – 200 kW on grinding worm/auger

High performance grinding within a wide capacity range is achieved through a low-tolerance, rigid design with smoothly shaped worms, hand-forged, welded, and ground superfinely by skilled Danish craftsmen combined with the smooth surfaces of a high precision CNC milling lining.

Shown here grinding whole frozen goat.

GRINDER – SINGLE WORM MG 330

The scansteel foodtech® MG 330 is equipped with either 75 kW or 90 kW electrical motor depending on specific grinding application(s). The MG 330 grinder is incredibly strong and reliable for both frozen blocks of meat raw material of any type as well as for certain bone-in products plus fresh meat raw materials. It comes with either a fixed or a loose pre-cutter depending on the grinding application.

Shown here grinding frozen Pig Skin.

Worm Trolley Machinery videos

This trolley designed by ScanSteel FoodTech allows operators to safely remove and insert the worm/auger for cleaning and inspection – without heavy lifting.

COMBIGRIND CG 225 / CG 300 / CG 300 HEAVY DUTY / CG 400 – THE BEAST

These truly unique and universal grinders provide first-class grinding results, fully comparable with and even surpassing those of conventionally specialised grinders for fresh, tempered, or deep-frozen blocks without changing anything but the incoming raw material to be ground, coarsely or finely, as required. scansteel foodtech® CombiGrind Grinders from Ø160 mm – Ø400 mm – 11 kW – 22 kW on breaking worm/auger and 30 kW – 200 kW on grinding worm/auger

High performance grinding within a wide capacity range is achieved through a low-tolerance, rigid design with smoothly shaped worms, hand-forged, welded, and ground superfinely by skilled Danish craftsmen combined with the smooth surfaces of a high precision CNC milling lining.

Equipped with a feeding and grinding worm/auger. Equipped with scanControl system, which monitors the frequency convertors on the two worms, regulating grinding speed in case of overloading.

Level sensor programme for automatic Start/Stop of machine to ensure machines are not running empty.

The CombiGrind machines have been designed to enable easy assembly and disassembly.

Logistics Machinery videos

Scan Giraff

Scansteel Foodtech A/S manufactures a wide range of screw conveyors, such as: Screw conveyors, Giraff screw conveyors and vertical screw conveyors.

The Scan Giraff has been designed with a particular focus on hygienically cleaning, accessibility, assembly and disassembly of all components.

- scansteel foodtech® Screw conveyors are inclined and horizontal.

- scansteel foodtech® Giraff screw conveyors are horizontal/vertical (as one unit)

- scansteel foodtech® Vertical screw conveyors are for mounting directly on grinder outlets.

Cut The Top Machinery videos

Cut The Top is a system that delivers one frozen block at a time to an infeed conveyor, from a stacked pallet.

Less lifting for staff, less staff required. DONE

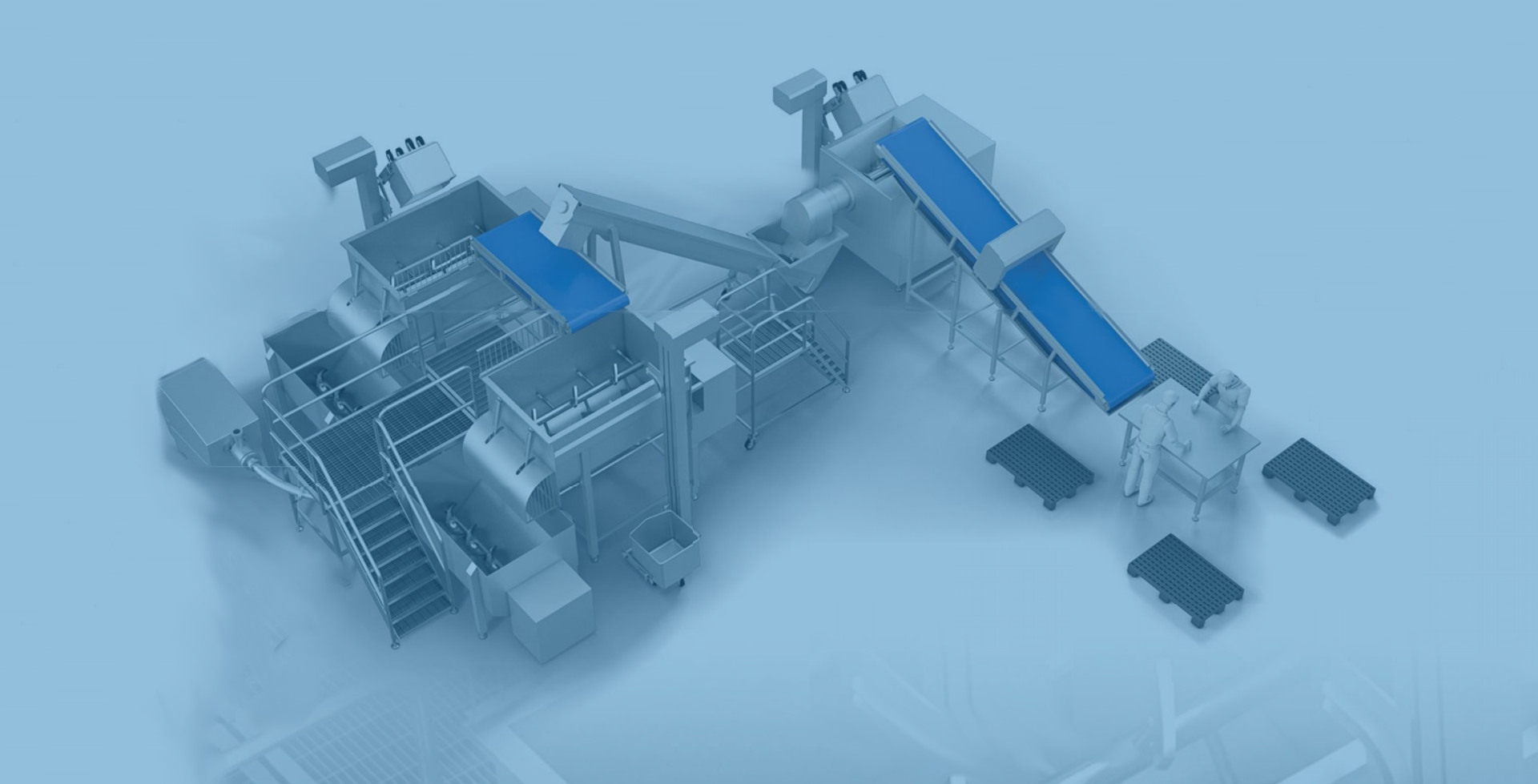

Mixer Grinder Machinery videos

Twin Shaft Mixer-Grinder 1250

The ScanSteel range of Mixer-Grinders are designed to meet individual requirements.

The 1250Ltr Mixer-Grinder shown here has been plated, equipped with CCR (Continuous Chip Removal also known as Bone Elimination System), cooling system in the grinding lining, mirro polished container, Twin Shaft Intermeshing.

Has a final grinding rate of 3000-10,000 kg/hour depending on meat raw material types and holeplates.

Mixer-Grinders sizes vary from 200ltr – 3,250lt.

Pallet Crusher Machinery videos

Whole Pallet Machinery videos

The scansteel foodtech® Whole Pallet Crusher, WPC, range is probably among the most comprehensive ranges available. scansteel foodtech A/S manufactures a range of Whole Pallet Crushers with either single claw or double claws with a standard infeed width of 1500mm or 2000 mm. A Whole Pallet Crusher is capable of crushing a pallet full of frozen together blocks which as such appear as one entire frozen block of, example only, 1200 x 800 x 1500 mm.

Pump Machinery videos

Super Pump Machinery videos

The scansteel foodtech® SuperPump series comprises 3 (three) different pump sizes. Correct choice of pump depends on several factors such as, but not limited to, pump capacity, material to be pumped, temperature, viscosity, and particle size – from pre-ground meat raw material to half a pork carcass. One significant feature is the double discharge outlet which dramatically minimizes (eliminates) fluctuations in pump capacity. Pump motors are designed according to pump application.

Twin Shaft Feed Pump (ContiPump) Machinery videos

The scansteel foodtech® ContiPump series is for less Heavy Duty applications such as, but not limited to, pet food premixes being fed into an emulsifier as well as for various buffer/storage/silo applications. The buffer hopper comes in 2 (two) versions: one single feeding screw or twin (two) feeding screws, where one screw feeds/drives the ContiPump while the other prevents/limits bridge building.

The scansteel foodtech® ContiPump series has been designed in such a way that the unit can function as a stand alone pump or can be designed to fully be integrated as part of an integrated solution with the scansteel foodtech® ContiPump and the scansteel foodtech® mixer series. In order to secure full hygiene solutions as well as having full access to both the mixer(s) and ContiPump for inspection/maintenance. The scansteel foodtech® ContiPumps can be placed on a “rail system” which makes it fully possible for a person to separate the ContiPump and mixer. At the same time, during production, the ContiPump is secure in “running position” in such a way that the ContiPump cannot be moved.

SuperGrind Machinery videos

SuperGrind 400/260 Machinery videos

Globally, the scansteel foodtech® SuperGrind 400/260 & 550/260 are probably the toughest and most Heavy Duty “Work Horses” among meat raw material grinders.

Designed specifically for global pet food and rendering industries for grinding of:

- Entire beef bones – all types including femur bones.

- Entire pork bones – all types including femur bones.

- Poultry bones – all types.

- Fish bones – all types.

- Pre-broken bones.

- Soft meat raw material

Video shows SuperGrind 400/260 grinding entire beef hides (Fresh) through a 4mm Holeplate, with a grinding capacity of 3000-6000 kg/hour.

SuperGrind 400/260 Machinery videos

The SuperGrind 400/260 in action grinding Horse bones with ease.