Food Machinery

At Food Machinery, Imports and Servicing we are proud to represent and be supported by ScanSteel FoodTech Group, Thurne, Komet, FMT, Viking Food Solutions and Revic. We are excited to be able to bring this range of Machines to New Zealand.

At Food Machinery, Imports and Servicing we are committed to provide our customers with high quality processing solutions with the highest hygienic and safety standards, in cooperation with our customers. This applies not only to machinery but also to outstanding maintenance and support.

Koment Germany

Komet is a leading European manufacturer of Packaging/Sealing Machinery

KOMET – YOUR PARTNER FOR VACUUM PACKING AND SOUS-VIDE COOKING

The company has been founded more than 70 years ago and since then we have been focusing on what we can do best: Developing, producing and selling machines for vacuum packing and cooking under vacuum for the industry, supermarkets, gastronomy and in particular for the butchers. Whatever we do, we always focus on our customers. They are in the focus of our thinking and doing. We are always looking for the best and most cost-efficient solutions that stand for highest quality “Made in Germany” and offer a comprehensive range of products for almost any need to our customers. All our employees are well educated and trained and have many years of experience in the line of business. The one-to-one service on site, the trusting cooperation with our partners on the selling and supplier side for decades, the family environment as well as flat hierarchies and the direct contact to all relevant contact persons – up to the entrepreneurial family are further indicators of our company. All these give our customers a maximum of continuity, quality, efficiency and promptness in all fields – yesterday, today and tomorrow! Yours KOMET team

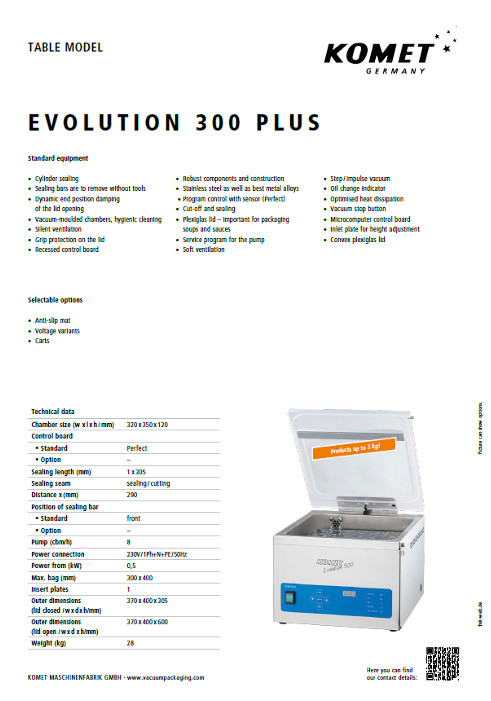

KOMET EVOLUTION 300 PLUS & PRO

Cylinder sealing • Sealing bars are to remove without tools • Dynamic end position damping of the lid opening • Vacuum-moulded chambers, hygienic cleaning • Silent ventilation • Grip protection on the lid • Recessed control board • Robust components and construction • Stainless steel as well as best metal alloys • Program control with sensor (Perfect) • Cut-off and sealing • Plexiglas lid – important for packaging soups and sauces • Service program for the pump • Soft ventilation • Step / impulse vacuum • Oil change indicator • Optimised heat dissipation • Vacuum stop button • Microcomputer control board • Inlet plate for height adjustment • Convex plexiglas

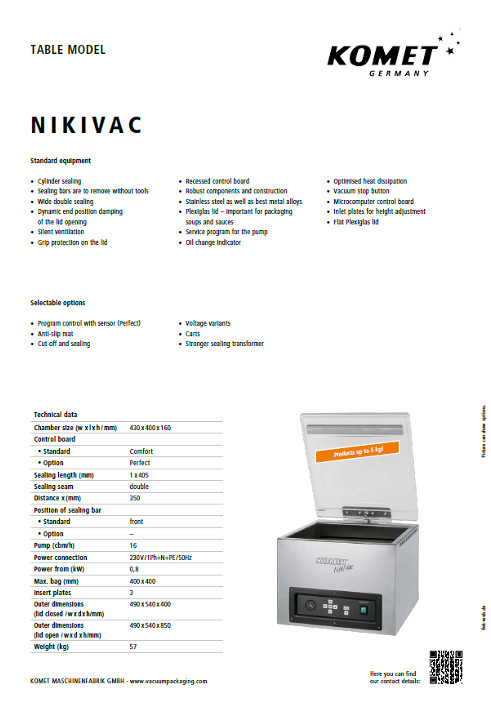

KOMET NIKIVAC

• Cylinder sealing • Sealing bars are to remove without tools • Wide double sealing • Dynamic end position damping of the lid opening • Silent ventilation • Grip protection on the lid • Recessed control board • Robust components and construction • Stainless steel as well as best metal alloys • Plexiglas lid – important for packaging soups and sauces • Service program for the pump • Oil change indicator • Optimised heat dissipation • Vacuum stop button • Microcomputer control board • Inlet plates for height adjustment • Flat Plexiglas lid

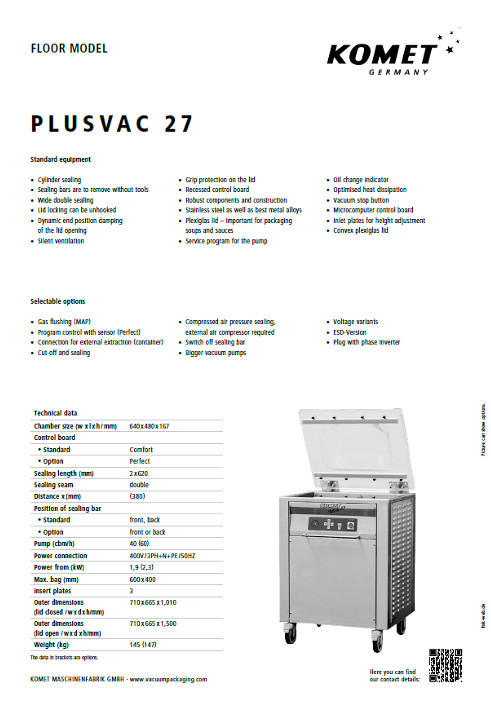

KOMET PLUSVAC VERSION 20 21 22 24 25 26 27

• Cylinder sealing • Sealing bars are to remove without tools • Wide double sealing • Lid locking can be unhooked • Dynamic end position damping of the lid opening • Vacuum-moulded chambers, hygienic cleaning • Silent ventilation • Grip protection on the lid • Recessed control board • Robust components and construction • Stainless steel as well as best metal alloys • Plexiglas lid – important for packaging soups and sauces • Service program for the pump • Oil change indicator • Optimised heat dissipation • Vacuum stop button • Microcomputer control board • Inlet plates for height adjustment • Convex plexiglas lid

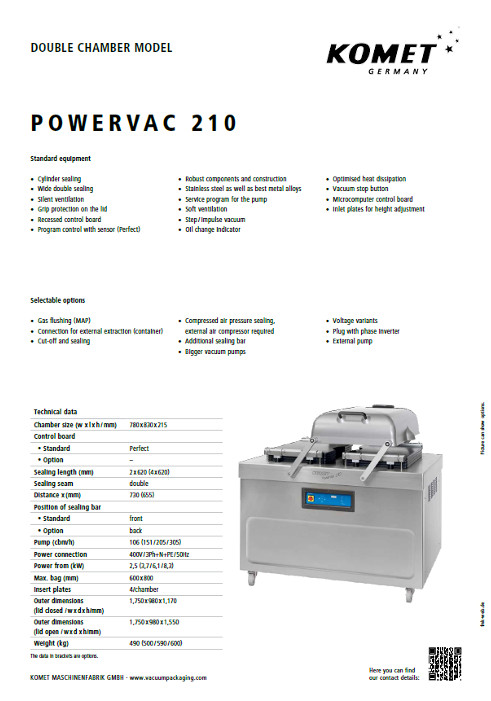

KOMET POWERVAC VERSION 200 210E

Cylinder sealing • Wide double sealing • Silent ventilation • Grip protection on the lid • Recessed control board • Program control with sensor (Perfect) • Robust components and construction • Stainless steel as well as best metal alloys • Service program for the pump • Soft ventilation • Step / impulse vacuum • Oil change indicator • Optimised heat dissipation • Vacuum stop button • Microcomputer control board • Inlet plates for height adjustment

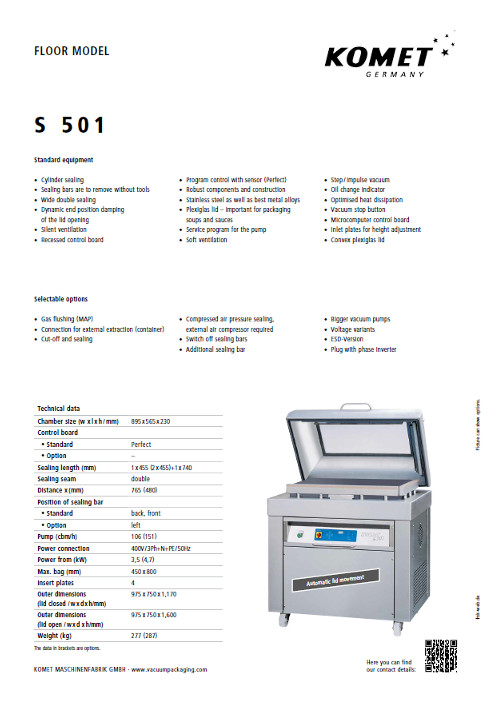

KOMET S 501

Cylinder sealing • Sealing bars are to remove without tools • Wide double sealing • Dynamic end position damping of the lid opening • Silent ventilation • Recessed control board • Program control with sensor (Perfect) • Robust components and construction • Stainless steel as well as best metal alloys • Plexiglas lid – important for packaging soups and sauces • Service program for the pump • Soft ventilation • Step / impulse vacuum • Oil change indicator • Optimised heat dissipation • Vacuum stop button • Microcomputer control board • Inlet plates for height adjustment • Convex plexiglas lid

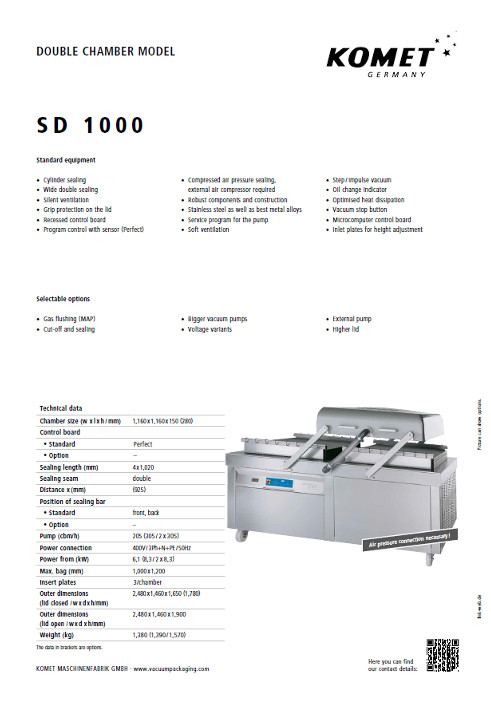

KOMET SD1000-EN

• Cylinder sealing • Wide double sealing • Silent ventilation • Grip protection on the lid • Recessed control board • Program control with sensor (Perfect) • Compressed air pressure sealing, external air compressor required • Robust components and construction • Stainless steel as well as best metal alloys • Service program for the pump • Soft ventilation • Step / impulse vacuum • Oil change indicator • Optimised heat dissipation • Vacuum stop button • Microcomputer control board • Inlet plates for height adjustment

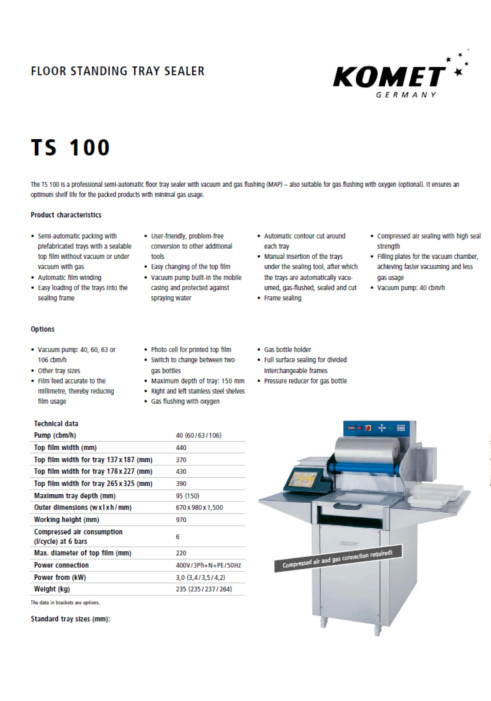

KOMET TS 100

The TS 100 is a professional semi-automatic floor tray sealer with vacuum and gas flushing (MAP) – also suitable for gas flushing with oxygen (optional). It ensures an optimum shelf life for the packed products with minimal gas usage.

FLOOR STANDING TRAY SEALER

• Semi-automatic packing with prefabricated trays with a sealable top film without vacuum or under vacuum with gas • Automatic film winding • Easy loading of the trays into the sealing frame • User-friendly, problem-free conversion to other additional tools • Easy changing of the top film • Vacuum pump built-in the mobile casing and protected against spraying water • Automatic contour cut around each tray • Manual insertion of the trays under the sealing tool, after which the trays are automatically vacuumed, gas-flushed, sealed and cut • Frame sealing • Compressed air sealing with high seal strength • Filling plates for the vacuum chamber, achieving faster vacuuming and less gas usage • Vacuum pump: 40 cbm/h

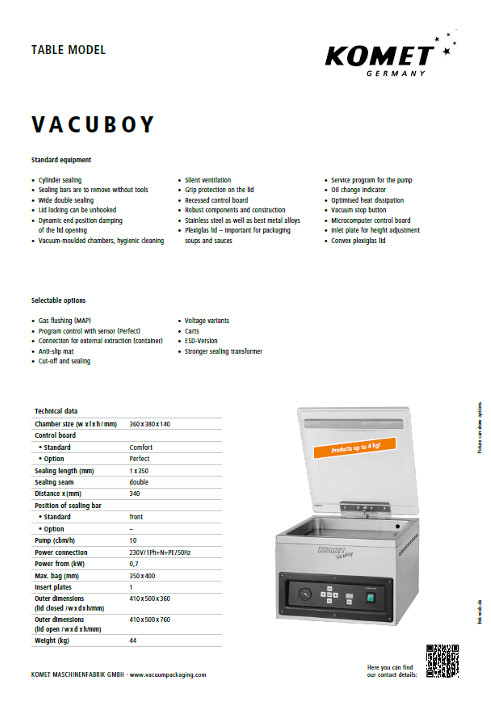

KOMET VACUBOY

Standard equipment • Cylinder sealing • Sealing bars are to remove without tools • Wide double sealing • Lid locking can be unhooked • Dynamic end position damping of the lid opening • Vacuum-moulded chambers, hygienic cleaning • Silent ventilation • Grip protection on the lid • Recessed control board • Robust components and construction • Stainless steel as well as best metal alloys • Plexiglas lid – important for packaging soups and sauces • Service program for the pump • Oil change indicator • Optimised heat dissipation • Vacuum stop button • Microcomputer control board • Inlet plate for height adjustment • Convex plexiglas lid Selectable options • Gas flushing (MAP) • Program control with sensor (Perfect) • Connection for external extraction (container) • Anti-slip mat • Cut-off and sealing • Voltage